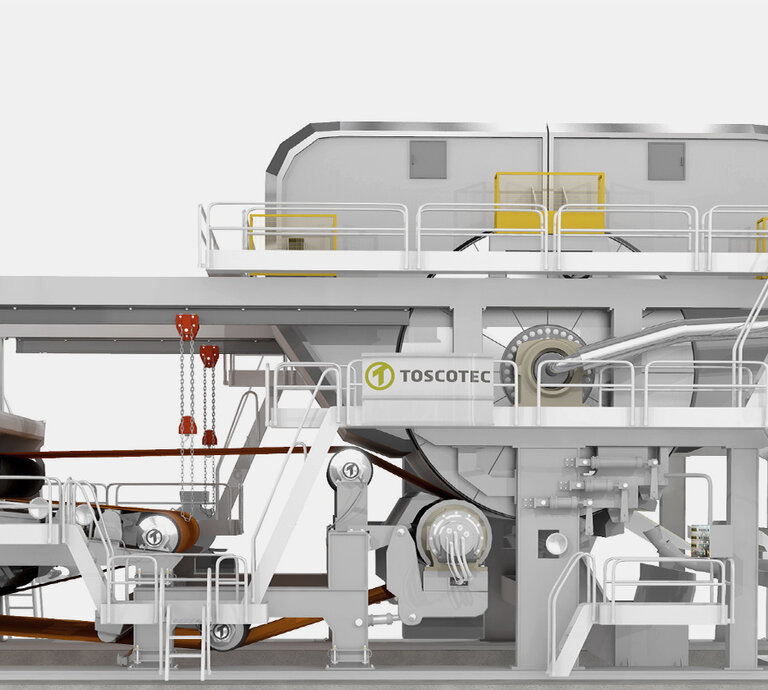

Press Section

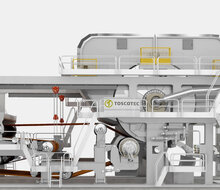

Paper machine press section represent a key area for rebuilds to improve quality of the paper and energy savings.

With its latest press section designs and references, Toscotec has focused on ease of operation and overall plant efficiency. Solutions have been developed on various grades to reduce free draws, paper breaks, and of course increase dryness out of the press section.

It is important to note that all these factors are strictly related to the mechanical properties and characteristics of the paper while focusing on the best compromise between dryness and bulk. Thanks to their flexibility, Toscotec press sections are the ideal solution both for new paper mills and rebuilds.

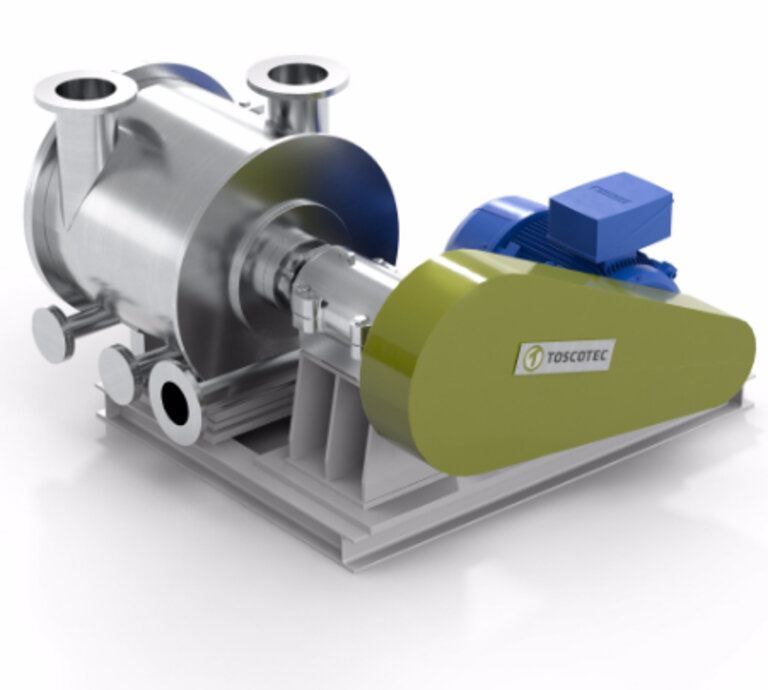

TT XPress and TT NextPress-P.

Toscotec strongly believes in shoe press technology and has been investing time and resources to develop specific products for all applications.

Toscotec offers specifically designed shoe presses:

- TT XPress: packaging, high nip load application.

- TT NextPress-P: high bulk paper, special paper application.

The TT XPress and TT NextPresss-P are the right solutions to improve moisture profile and increase paper dryness out of the press section.

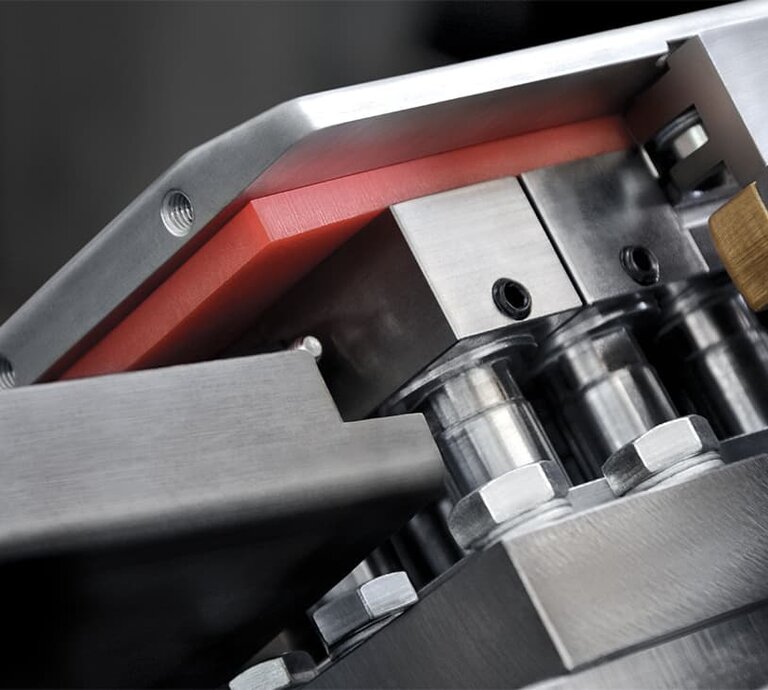

The shoe press nip is formed between the counter roll and full width shoe.

For the TT XPress, this nip ranges from 200 to 350 mm.

The resulting nip dwell time is approximately three times longer than that offered by a conventional Jumbo press. Design Nip load for the packaging grades can ramp up 1,300-1,400 kN/m. TT NextPress-P is tailored with different combinations of Nip Load, shoe width and diameter according to the specific application.

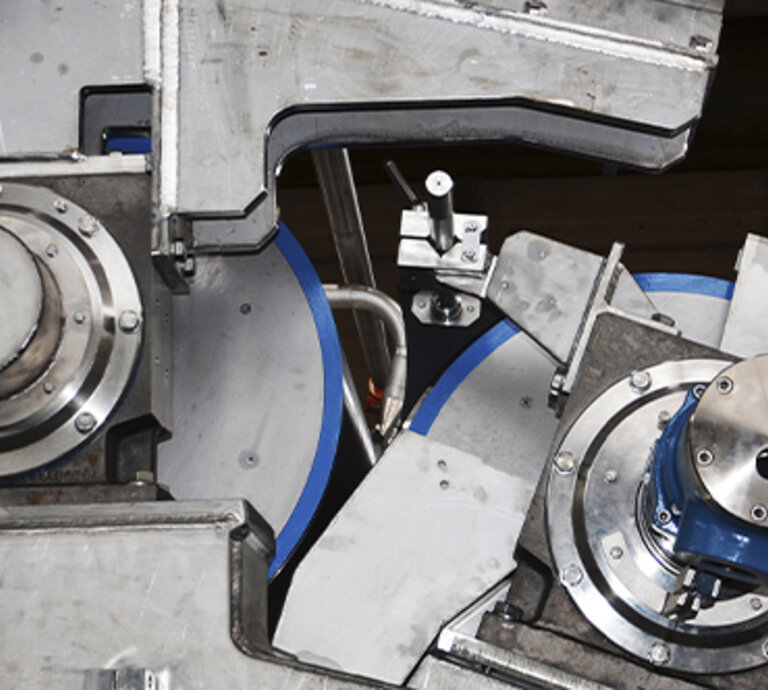

TT XPress and TT NextPress-P feature a double-row loading system of pistons. With this feature, it is possible to adjust the tilt (different oil pressure on the two rows) while the machine is running; hence the loading curve can be tuned in accordance with the paper grade and desired mechanical characteristics with relation to the dryness out of the press section.

The TT XPress and TT NextPress-P are flexible units that can be easily installed and adapted for press rebuilds.

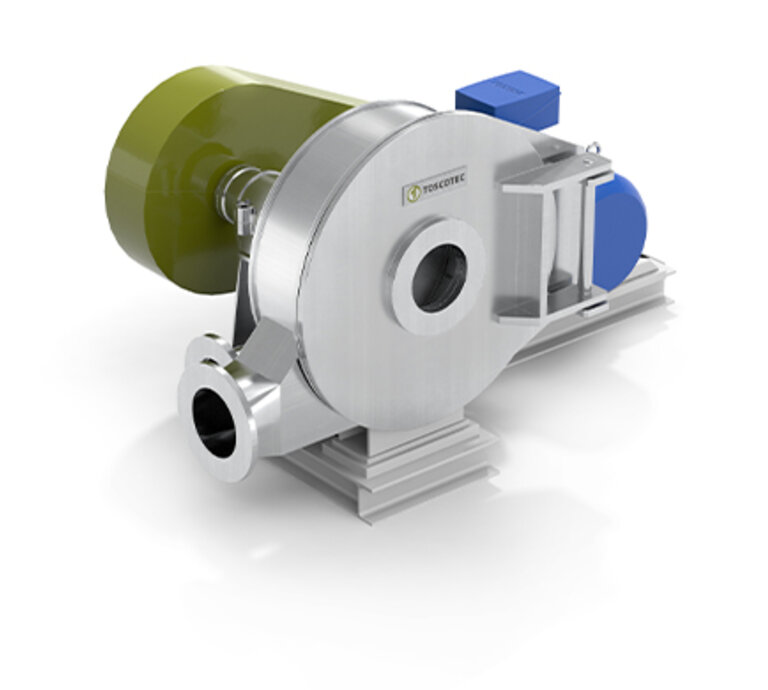

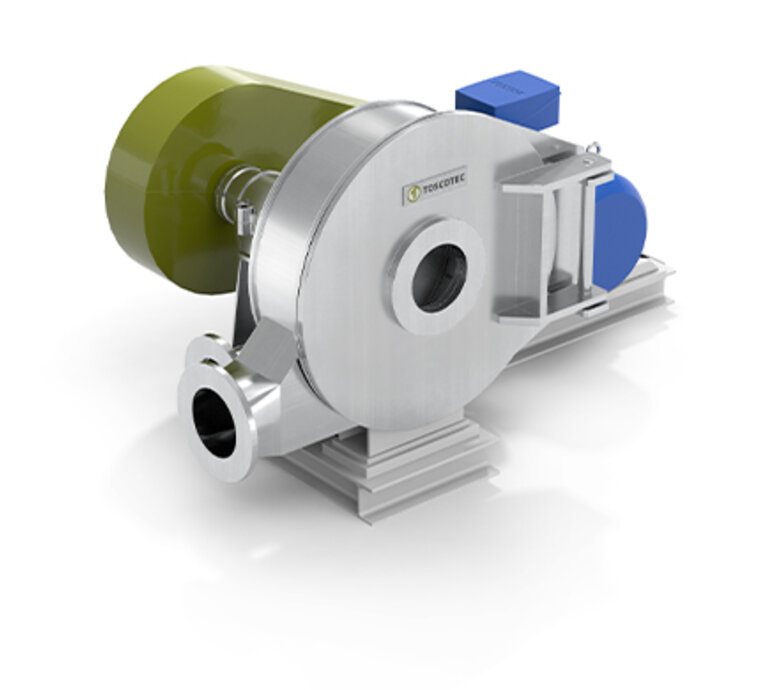

TT CouchRoll, SuctionPressRoll and PickUp.

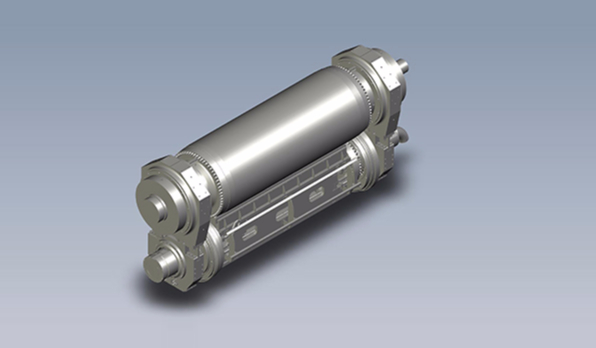

Toscotec product portfolio includes suction rolls suitable to be used as couch roll, press roll, suction pick-up or transfer roll.

The design is tailored according to the application and can satisfy all needs with relation to the diameter, shell material and covers. The new design has enabled rolls with internal bearings to be removed in conjunction with the internal suction box for easy maintenance.

Thanks to the Toscotec design, suction rolls can also be supplied without internal bearings and with shaft-mounted gearbox drive where it is required. Suction rolls feature the deckle adjustment if required by the application.

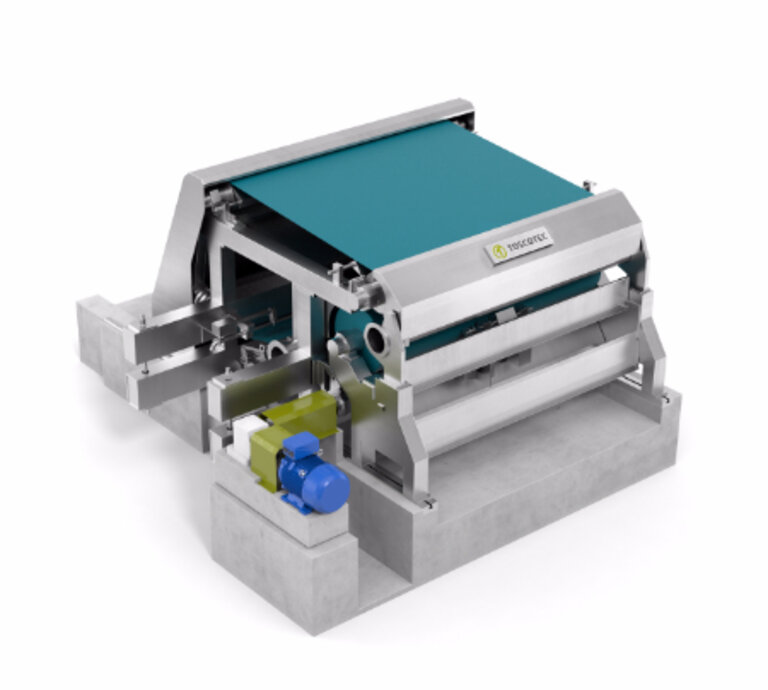

TT JumboPress

With press roll diameters up to 1,550 mm, the TT JumboPress offers a solution combining lower installation costs and efficient water removal.The TT JumboPress can be an alternative where the investment or requirements don’t justify a shoe press installation. Jumbo presses may be supplied single or double-felted and covered with elastic or ceramic material.

Paper & Board Machines

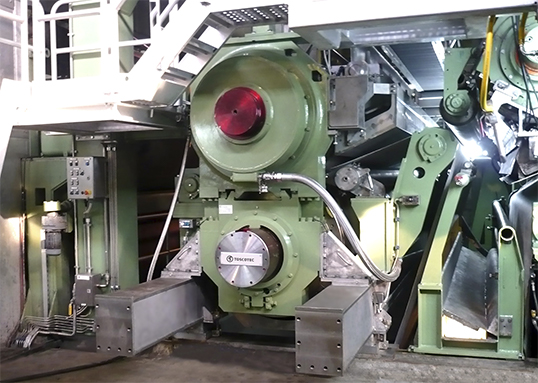

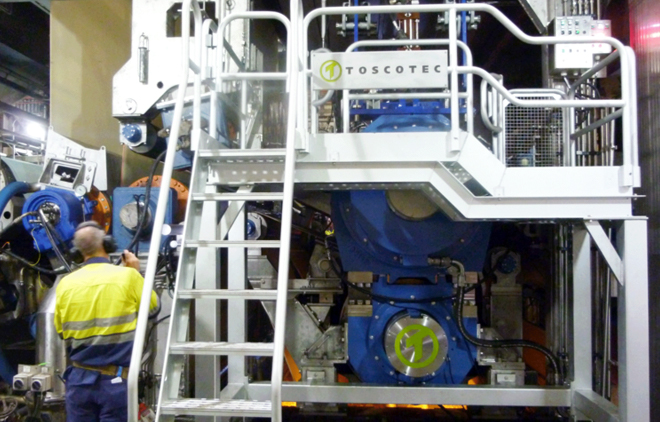

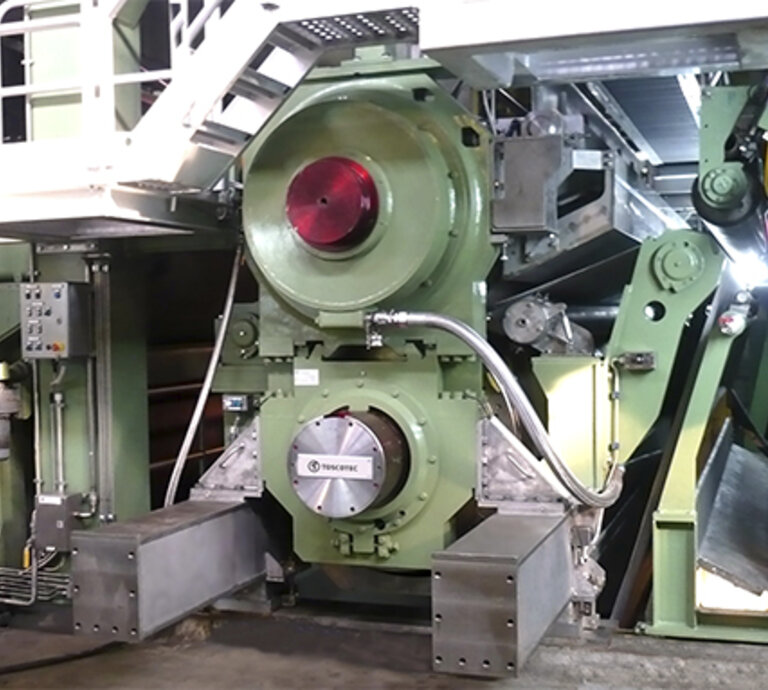

Visy Paper started up VP5 in Melbourne, Australia, after Toscotec's Press Section Upgrade

Visy Paper PM5 has successfully started up in end of March 2015 at Coolaroo, Melbourne – Australia, after a press section upgrade carried out by the Italian company Toscotec. VP5 paper machine produces coating base sheet and test liner for export, from recycled paper.

Product finder

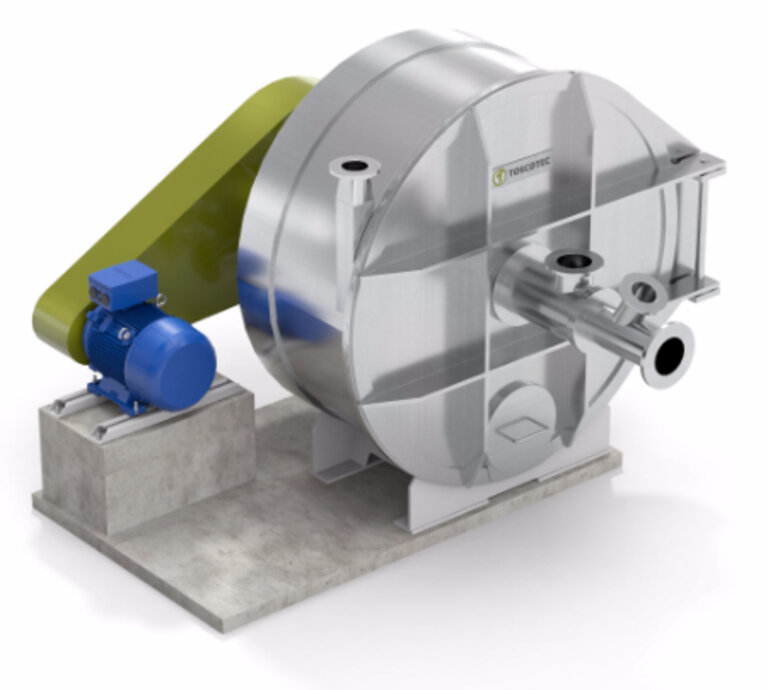

Broke Pulper

TT MBP. The Toscotec Broke Pulper TT MBP is designed to be installed under machine both in tissue, paper and board applications.

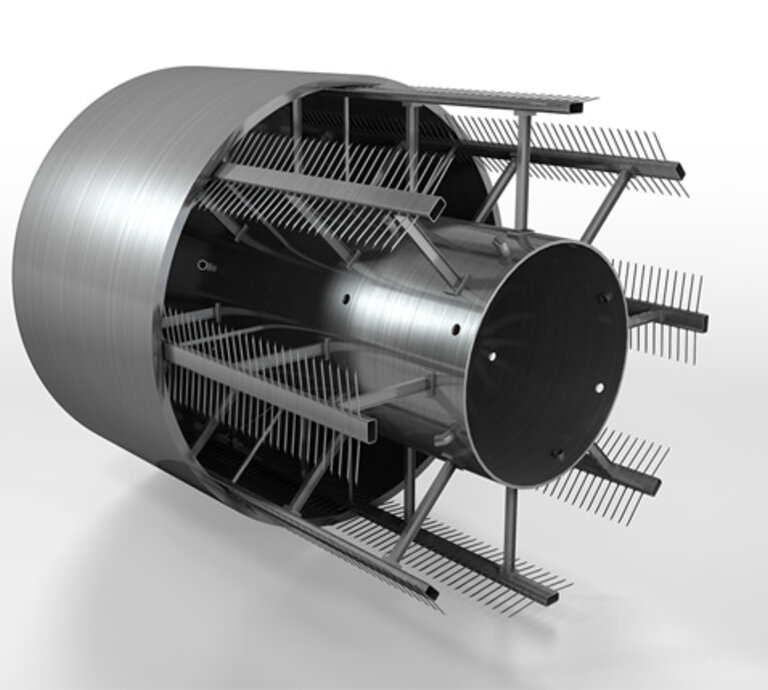

Rotating Screen

TT RS. The Toscotec Rotating Screen TT RS is used in recycled paper stock preparation plants to de-water the coarse rejects coming from upstream cleaning equipment.

Ragger

TT RG. For the proper performance of a continuous pulper working with recycled paper (Toscotec Low Density Pulper), a cleaning unit such as the ragger TT RG is required to be installed.

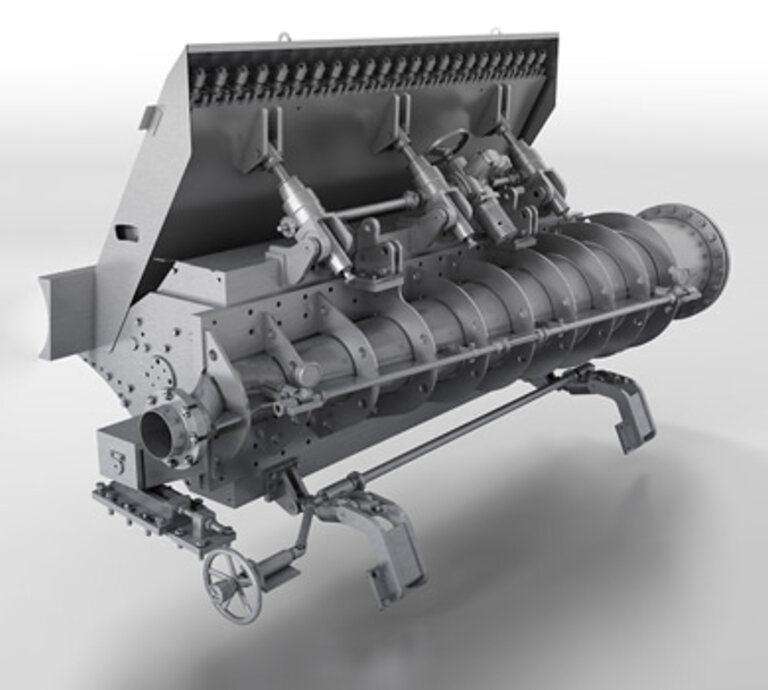

Low Density Pulper

TT TM. Optimized to work with heavily contaminated recycled paper or with rewinder trims, the Toscotec Low Density Pulper TT TM is designed to perform an extremely efficient and low energy slushing in continuous mode and to remove rejects without breaking them.

Medium Density Pulper

TT VP. Suitable to work both with virgin pulp, broke, recycled paper and non-wood fibers, the Toscotec Medium Density pulper TT VP is designed to perform an extremely efficient and low energy slushing in discontinuous mode.

Turbo Separator

TT TMC. The Toscotec Turboseparator TT TMC is installed in recycled paper stock preparation lines as primary screen to treat the accept stream of the Toscotec Low Density Pulper.

Vortiscreen 3 Series

TT VS-3. The Toscotec Vortiscreen TT VS-3 can be installed as the only coarse screen in converting broke lines or as the last tail screening stage for the treatment of the rejects coming from drilled Toscotec Superscreens in recycled paper processing lines.

Vortiscreen 1 Series

TT VS-1. The Toscotec Vortiscreen TT VS-1 is used in recycled paper stock preparation plants mainly for the detrashing of the continuous TM Pulpers and as a dumping machine of high consistency batch pulpers.

Superscreen

TT SS. The Toscotec Superscreen TT SS is a horizontal screen with basket and rotor designed to be installed as a coarse or fine screen in recycled paper stock preparation plants. It is optimal to treat stock up to a working consistency of 5%.

High Density Cleaner

TT HDC. Engineered to work both with virgin pulp and recycled paper, the Toscotec High Density Cleaner TT HDC is designed to reliably remove heavier than fiber contaminants, suspended in consistencies up to 6%, directly after the pulper.

Thickening Screw

TT CA. The Toscotec Thickening Screw TT CA is an inclined screw thickener; it can be configured as a Single Unit or as Combined Units (up to 3 Units on a single stand and with only one feeding headbox) for higher capacity and reduced footprint.

Wire Washer

TT CW. The Toscotec Wire Washer TT CW is used to obtain an efficient removal of ashes, inks, glues, and fines by means of low consistency stock washing and consequent thickening.

Short Approach Flow System

TT SAF. Toscotec Short Approach Flow TT SAF, patented by Toscotec since 2012, allows every mill, new or existing one, to reduce energy consumptions and installation space, without compromises in terms of performances.

Vibrating Screen

TT V. The Toscotec Vibrating Screen TT V can be used as final stage for rejects de-watering after other screens such as vortiscreens, superscreens and pressure screens.

Pressure Screen

TT AFS. The Toscotec Pressure Screen TT AFS is designed to be installed in the approach flow system as final protection of the headbox.

Short Approach Flow System

TT SAF. Toscotec Short Approach Flow TT SAF, patented by Toscotec since 2012, allows every mill, new or existing one, to reduce energy consumptions and installation space, without compromises in terms of performances.

Vibrating Screen

TT V. The Toscotec Vibrating Screen TT V can be used as final stage for rejects de-watering after other screens such as vortiscreens, superscreens and pressure screens.

Pressure Screen

TT AFS. The Toscotec Pressure Screen TT AFS is designed to be installed in the approach flow system as final protection of the headbox.

Environment

Dust Removal System, Mist Removal System, Heating & Ventilation System

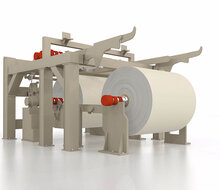

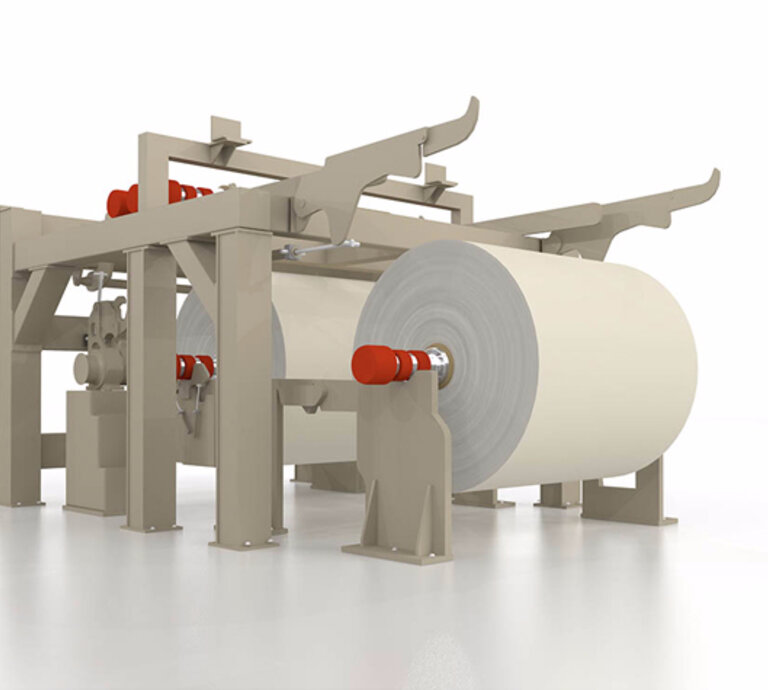

Reel Section

Quality rolls for rewinder operation

Hoods & Air system

Toscotec customizes the design of its TT Hood based on the customer’s needs and the overall drying configuration of the tissue machine, including the Steel Yankee Dryer.

Steam and Condensate System

As an auxiliary system of the Steel Yankee Dryer, Toscotec’s Steam and Condensate System is optimized to operate in association with TT SYD to allow it to achieve its maximum drying capacity.

Steel Yankee Dryer

Toscotec is both the inventor and the leading supplier of Steel Yankee Dryers worldwide.

Press

Paper machine press section represent a key area for rebuilds to improve quality of the paper and energy savings.

Headbox

TT Headbox delivers optimal sheet formation, because its design is custom-made based on the specific product needs of the customer. It operates at a high consistency, thereby reducing energy consumption.

Environment

Dust Removal System, Mist Removal System, Heating & Ventilation System

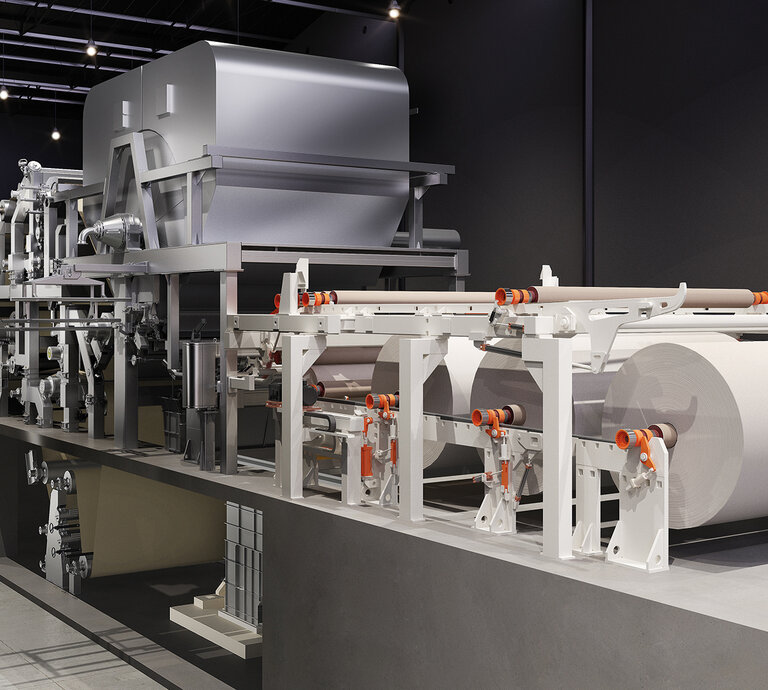

AHEAD Line

The AHEAD Line is made of Toscotec’s Conventional Wet Press Tissue machines. Every AHEAD tissue machine is custom-made.

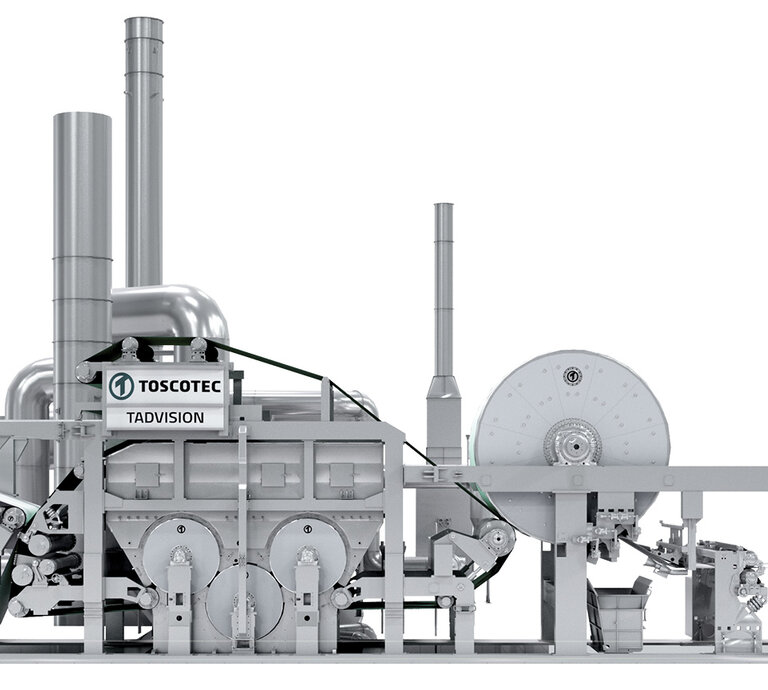

TADVISION® Line

Toscotec’s TADVISION® Line ensures optimal bulk, softness and absorbency. Toscotec upgraded the design of its TADVISION® Line machine in order to achieve superior bulk, absorbency, and outstanding results in energy consumption.

INGENIA Line

INGENIA is a new concept tissue machine to produce premium quality structured tissue paper.

Toscotec OPTIMA Line

OPTIMA rewinders: the best technology to preserve softness and quality.

P&B Machines

Toscotec can satisfy all the needs related to the paper machine improvement

Reel Section

Section Quality rolls for rewinder operation.

Tail Feeding System

The perfect tool for new machines or to improve the efficiency and safety of an existing line.

Online sizing and calendering

Surface improvement solutions for a stronger paper

Drying Section

The most famous well-proven TT SteelDryer and drive concepts.

Press Section

Tailored press technologies, inlcuding Shoe Press, according to the applications.

Forming Section

State-of-the-art drainage equipment is properly configured on a Toscotec fourdrinier to reach the best quality results.

Headbox

Toscotec’s headbox line can satisfy all customer needs in terms of production, quality and specific application.