Toscotec OPTIMA Line

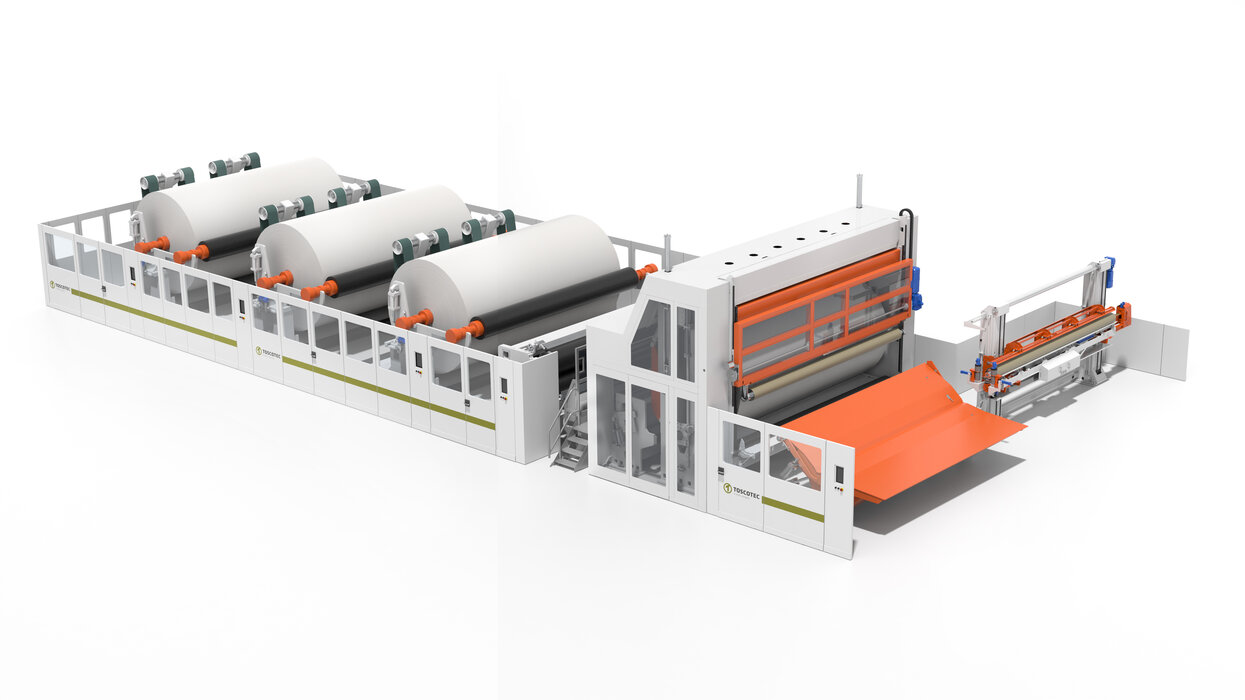

OPTIMA rewinders: the best technology to preserve softness and quality.

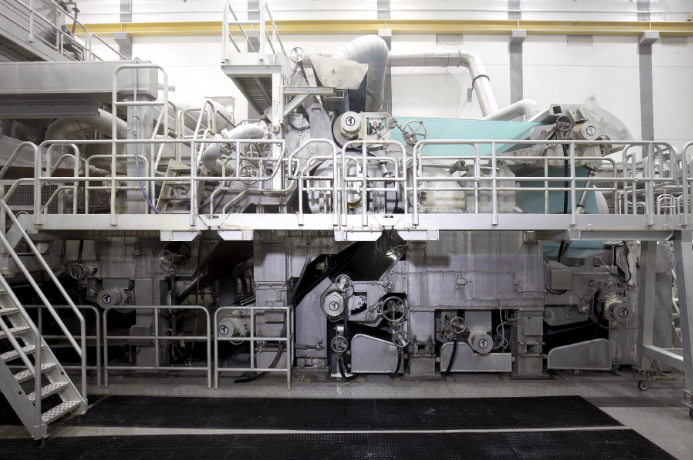

Toscotec OPTIMA line is made of high-performance rewinders that represent the perfect match for Toscotec AHEAD high-speed tissue machines.

OPTIMA rewinders are fitted with a dedicated control system of all winding operations, which, in connection with a customized software, is able to adjust the NIP control automatically. The sensors installed on the machine send continuous feedback to the control system, which makes sure that the actual NIP of the wound reel is detected and adjusted in real time. As a result, the NIP control preserves the softness and the bulk of the parent rolls and guarantees optimal reel uniformity.

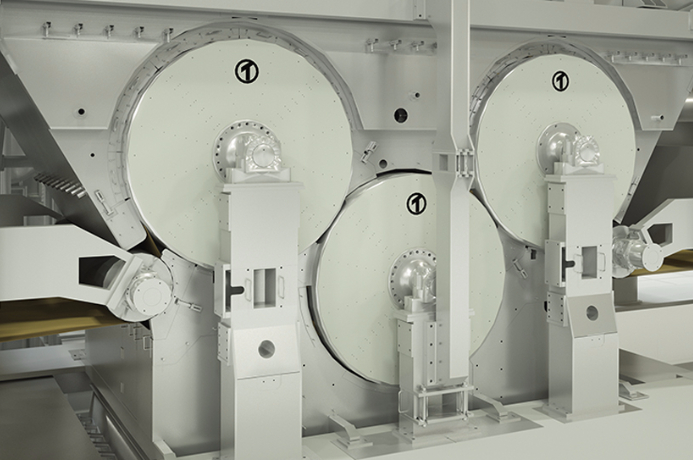

OPTIMA rewinders install up to four unwinding stands equipped with a compensation system for out-of-round parent rolls and CWA (Center Wind Assist) control. They can also install a calender fitted with skew or crown control, slitting groups with independent and motorized counter knives, an automatic shaft puller and core loading system.

| OPTIMA SHAFTLESS | OPTIMA 1800 | OPTIMA 2200 | OPTIMA 2600 | |

|---|---|---|---|---|

| Basis weight | 12:40 gsm | 12:40 gsm | 12:40 gsm | 12:40 gsm |

| Speed up to | 1,100 mpm | 1,300 mpm | 1,800 mpm | 1,800 mpm |

| Finished reel | 2,000 mm | 1,800 mm | 2,200 mm | 2,600 mm |

| Trim width | up to 5,600 | up to 3,600 mm | up to 3,600 mm | up to 5,600 mm |

| Carrying drum diameter | 500 - 600 - 750 mm | 500 mm | 600 mm | 750 (900 optional) mm |

| Shaft handling | Manual | Automatic (external) | Automatic (external) | |

| Features | Hydraulic, tail threading | Pneumatic Optional: Tail threading (rewinder) | Hydraulic, tail threading Optional: NIP Control Tail threading from unwind stands DRS CWA | Hydraulic, tail threading Optional: NIP Control Tail threading from unwind stands DRS CWA |

Product finder

Broke Pulper

TT MBP. The Toscotec Broke Pulper TT MBP is designed to be installed under machine both in tissue, paper and board applications.

Rotating Screen

TT RS. The Toscotec Rotating Screen TT RS is used in recycled paper stock preparation plants to de-water the coarse rejects coming from upstream cleaning equipment.

Ragger

TT RG. For the proper performance of a continuous pulper working with recycled paper (Toscotec Low Density Pulper), a cleaning unit such as the ragger TT RG is required to be installed.

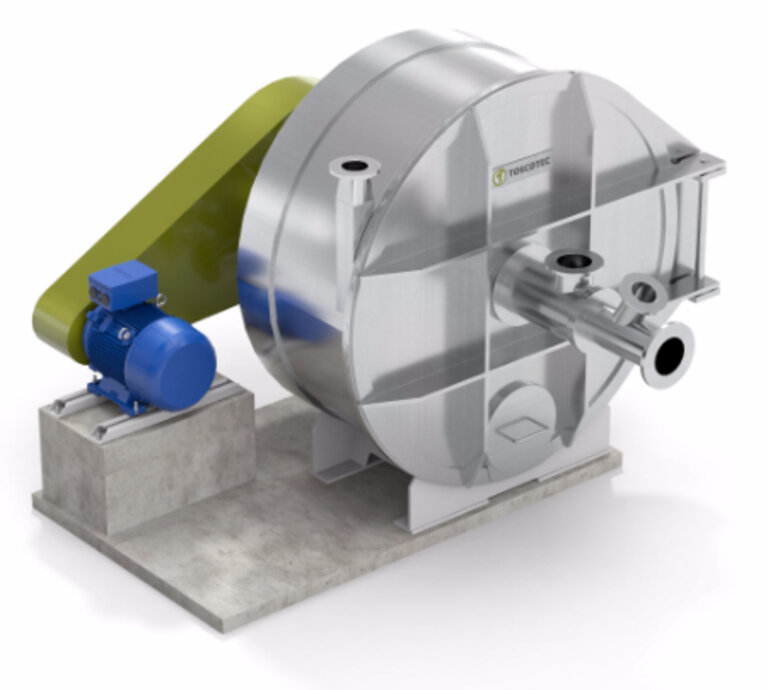

Low Density Pulper

TT TM. Optimized to work with heavily contaminated recycled paper or with rewinder trims, the Toscotec Low Density Pulper TT TM is designed to perform an extremely efficient and low energy slushing in continuous mode and to remove rejects without breaking them.

Medium Density Pulper

TT VP. Suitable to work both with virgin pulp, broke, recycled paper and non-wood fibers, the Toscotec Medium Density pulper TT VP is designed to perform an extremely efficient and low energy slushing in discontinuous mode.

Turbo Separator

TT TMC. The Toscotec Turboseparator TT TMC is installed in recycled paper stock preparation lines as primary screen to treat the accept stream of the Toscotec Low Density Pulper.

Vortiscreen 3 Series

TT VS-3. The Toscotec Vortiscreen TT VS-3 can be installed as the only coarse screen in converting broke lines or as the last tail screening stage for the treatment of the rejects coming from drilled Toscotec Superscreens in recycled paper processing lines.

Vortiscreen 1 Series

TT VS-1. The Toscotec Vortiscreen TT VS-1 is used in recycled paper stock preparation plants mainly for the detrashing of the continuous TM Pulpers and as a dumping machine of high consistency batch pulpers.

Superscreen

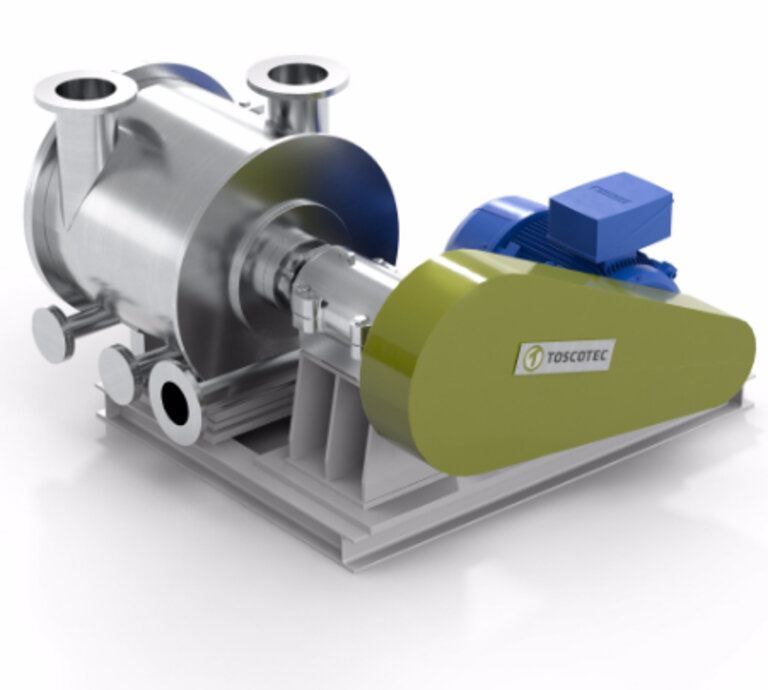

TT SS. The Toscotec Superscreen TT SS is a horizontal screen with basket and rotor designed to be installed as a coarse or fine screen in recycled paper stock preparation plants. It is optimal to treat stock up to a working consistency of 5%.

High Density Cleaner

TT HDC. Engineered to work both with virgin pulp and recycled paper, the Toscotec High Density Cleaner TT HDC is designed to reliably remove heavier than fiber contaminants, suspended in consistencies up to 6%, directly after the pulper.

Thickening Screw

TT CA. The Toscotec Thickening Screw TT CA is an inclined screw thickener; it can be configured as a Single Unit or as Combined Units (up to 3 Units on a single stand and with only one feeding headbox) for higher capacity and reduced footprint.

Wire Washer

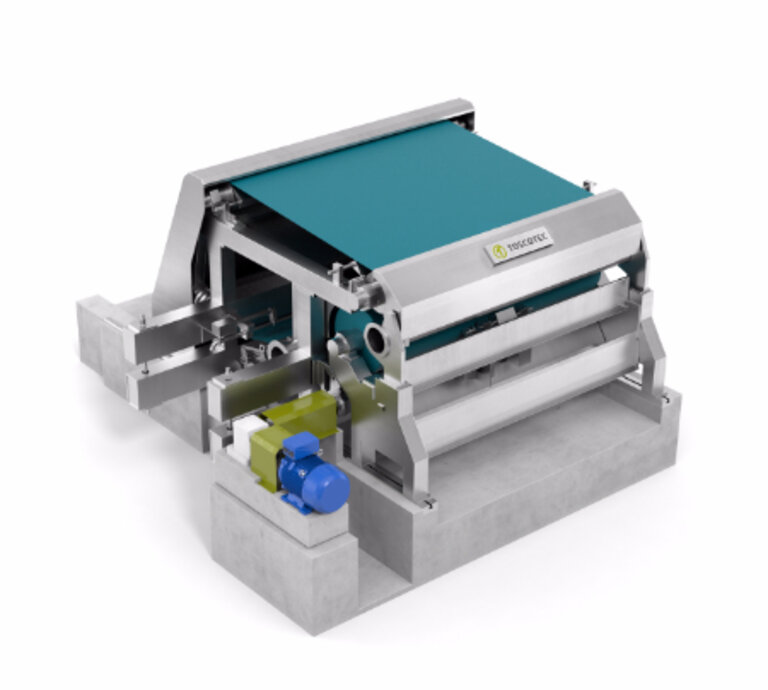

TT CW. The Toscotec Wire Washer TT CW is used to obtain an efficient removal of ashes, inks, glues, and fines by means of low consistency stock washing and consequent thickening.

Short Approach Flow System

TT SAF. Toscotec Short Approach Flow TT SAF, patented by Toscotec since 2012, allows every mill, new or existing one, to reduce energy consumptions and installation space, without compromises in terms of performances.

Vibrating Screen

TT V. The Toscotec Vibrating Screen TT V can be used as final stage for rejects de-watering after other screens such as vortiscreens, superscreens and pressure screens.

Pressure Screen

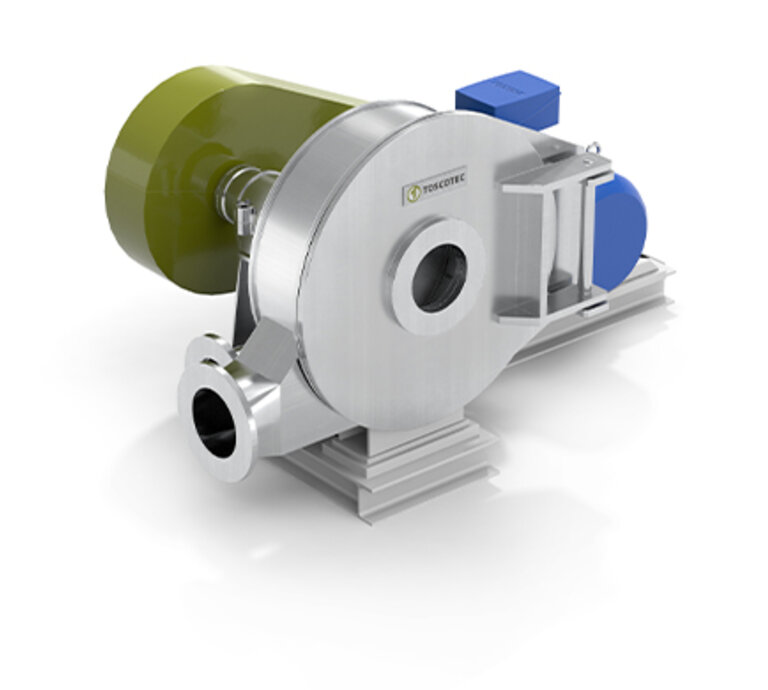

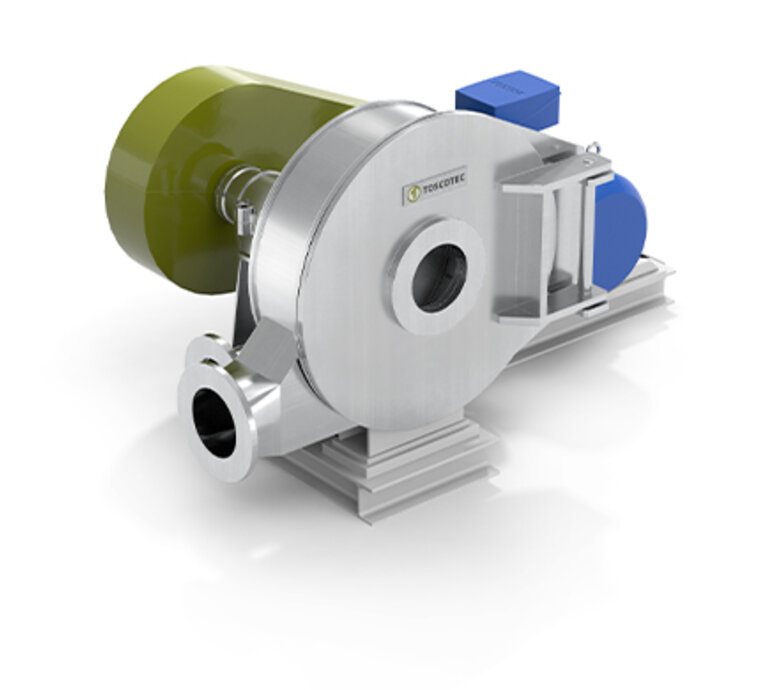

TT AFS. The Toscotec Pressure Screen TT AFS is designed to be installed in the approach flow system as final protection of the headbox.

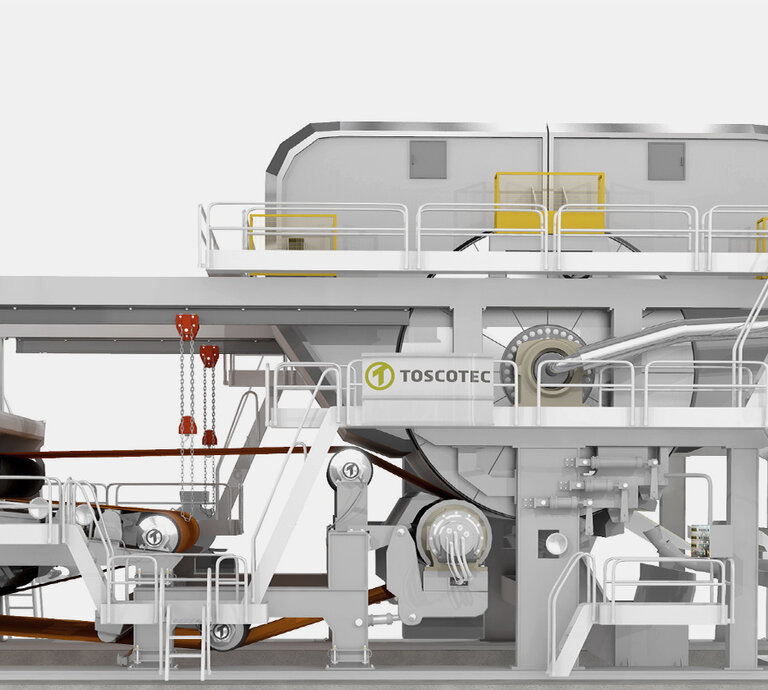

AHEAD Line

The AHEAD Line is made of Toscotec’s Conventional Wet Press Tissue machines. Every AHEAD tissue machine is custom-made.

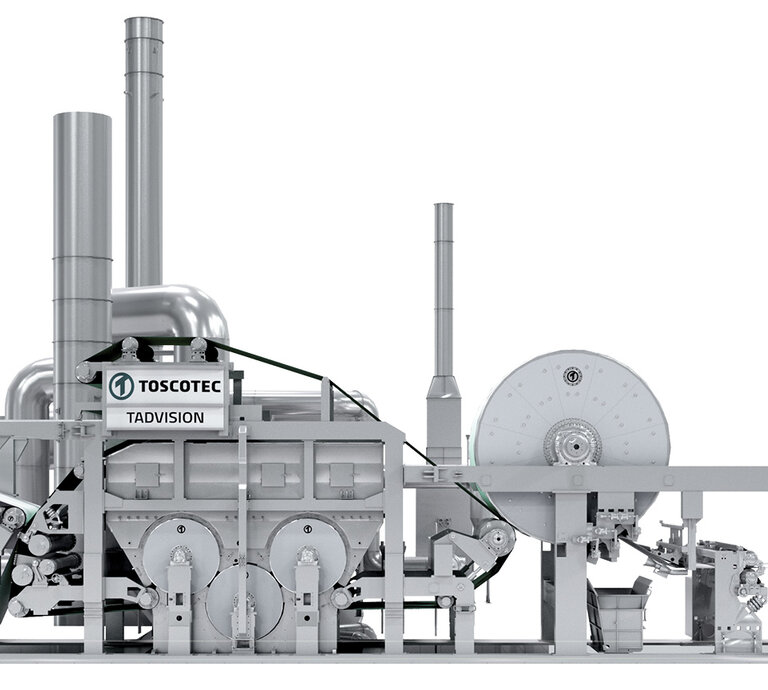

TADVISION® Line

Toscotec’s TADVISION® Line ensures optimal bulk, softness and absorbency. Toscotec upgraded the design of its TADVISION® Line machine in order to achieve superior bulk, absorbency, and outstanding results in energy consumption.